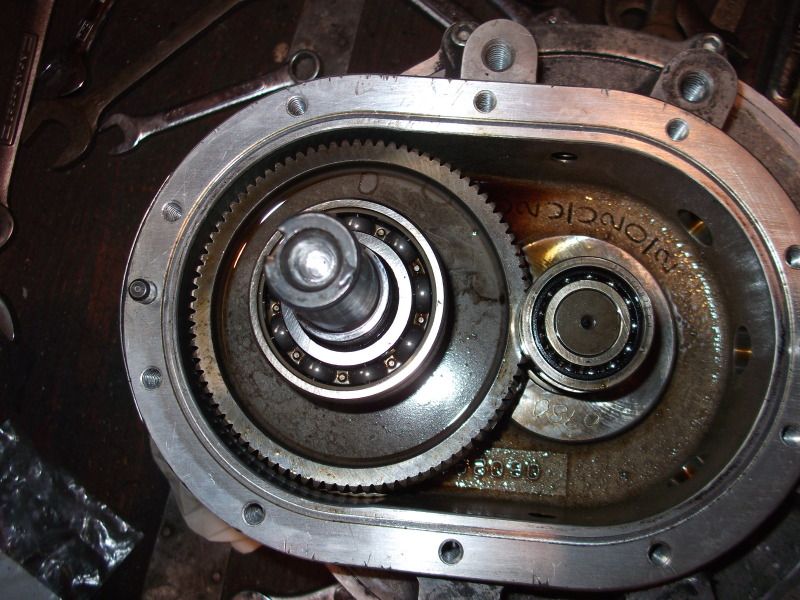

I had the bolt break that holds the pulley on. After trying to get it out with an ez out, I'm left with messed up threads.

Anyone think it's possible for a machine shop to redrill and tap the hole ? It would have to be done with the head unit still together. If I take the input shaft out I may as well just buy a new one.

Reply With Quote

Reply With Quote

Bookmarks