-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

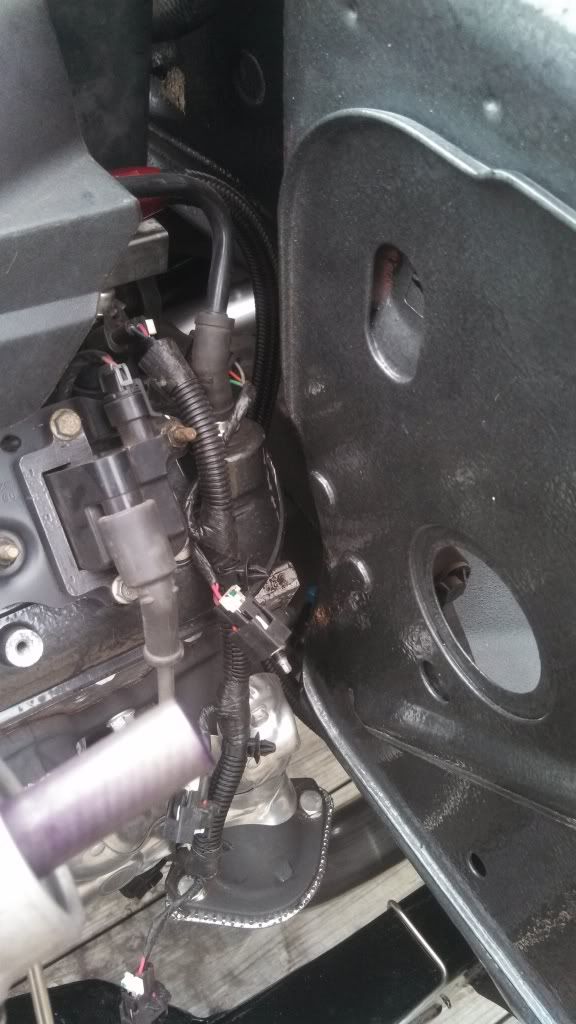

well the clutch goodies showed up

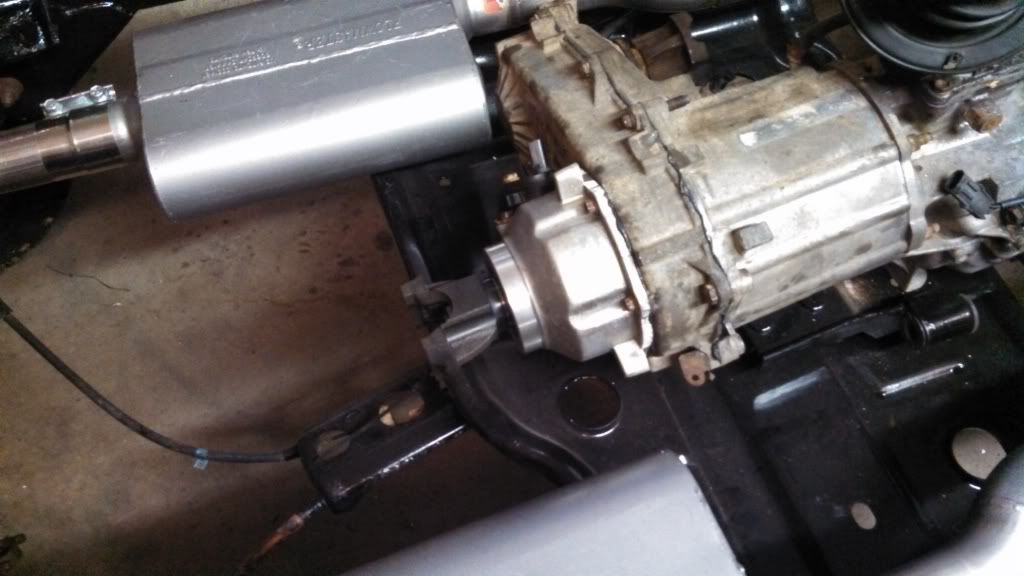

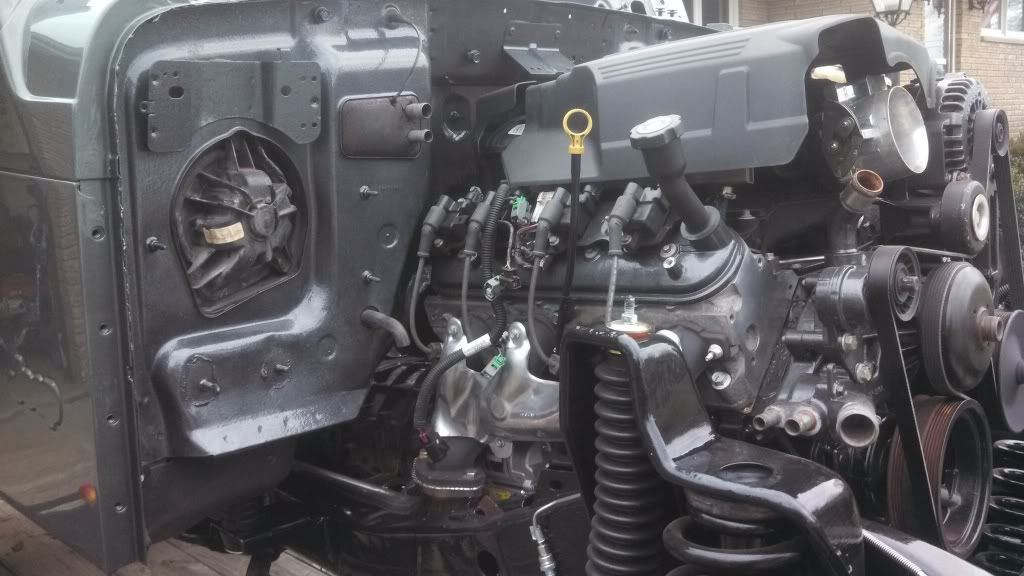

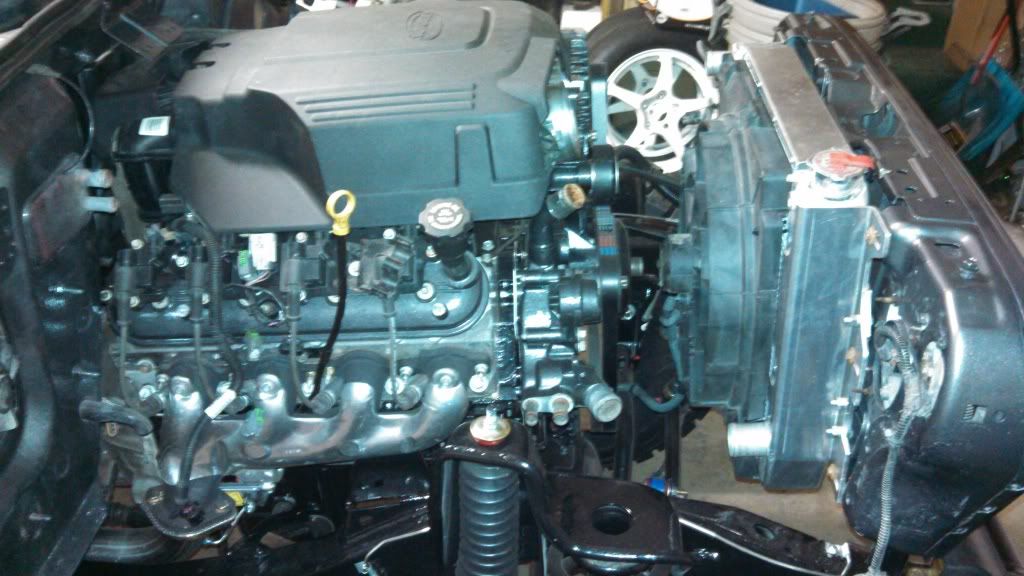

finally got the motor in the garage to be torn down and inspected, ordered up a few goodies should have motor back together by weekend

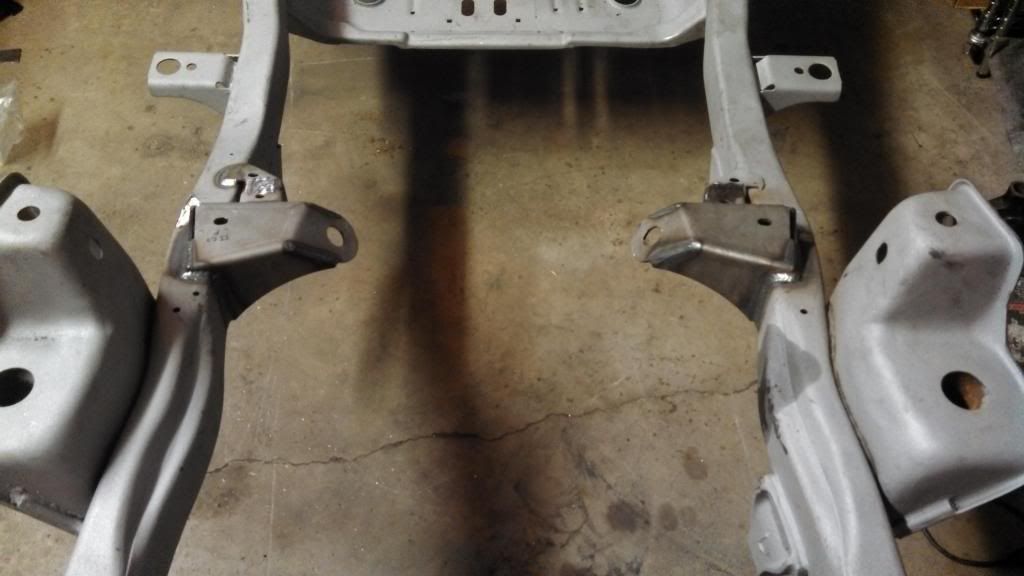

not shown is the replacement front axle assembly that was picked up over the weekend

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

To some these pics of the welds were done a few years ago, ive since surpassed this skill level

-

Banned

since the next step of this project was to replace the brake lines, i went ahead and contacted INLINE TUBE and purchased their stainless steel brake lines, also decided to use the Earl's prolite 350 hose i had from a previous build. Contacted summit and ordered up the fittings required to do this job. Decided to keep the Jeep returnless which made things easiler

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

-

Banned

Posting Permissions

Posting Permissions

- You may not post new threads

- You may not post replies

- You may not post attachments

- You may not edit your posts

-

Forum Rules

Reply With Quote

Reply With Quote

Bookmarks