good work as usual Mark....

Does your car have a 2-step on it?

good work as usual Mark....

Does your car have a 2-step on it?

-JOHN

Carburetors and SAE wrenches.................

Buy Made in the USA - It Matters.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Meet the $1,200+ stripped pivot ball hole...

The threads look halfway usable from this angle, but the other side of the hole is smooth. Technically I could drill it out and do a helicoil style repair, but I've been on the fence about doing the SFI bell housing conversion/upgrade. This pushed me over the fence. Wife also said "just do the upgrade now. You know you'll regret not upgrading it". She's right.Unfortunately that doesn't make it any cheaper.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

This is the most expensive TR3650 in the history of the world.

Should've bought a magnum. :)

-JOHN

Carburetors and SAE wrenches.................

Buy Made in the USA - It Matters.

Yep, even though a Magnum would have been roughly the same investment unless I bought it used.

Live and learn. It's been an expensive process for sure. Money into that I'll never get back out of the car, so I'd better enjoy it. At least it should hold up to any abuse I throw at it, and it will pass any tech inspection.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Lol, from the back of the block, to the tail shaft, I likely have more than my car is "worth" (SFI bell, adapter plate, custom flywheel, RXT clutch, G Force) .... Zero value add.

It's really easy to woulda shoulda coulda stuff to death, you make decisions as it moves forward, then realize your mistakes after you run into them.

I could probably build my car over for 1/4 of what's in it if I just woulda spent it all up front.

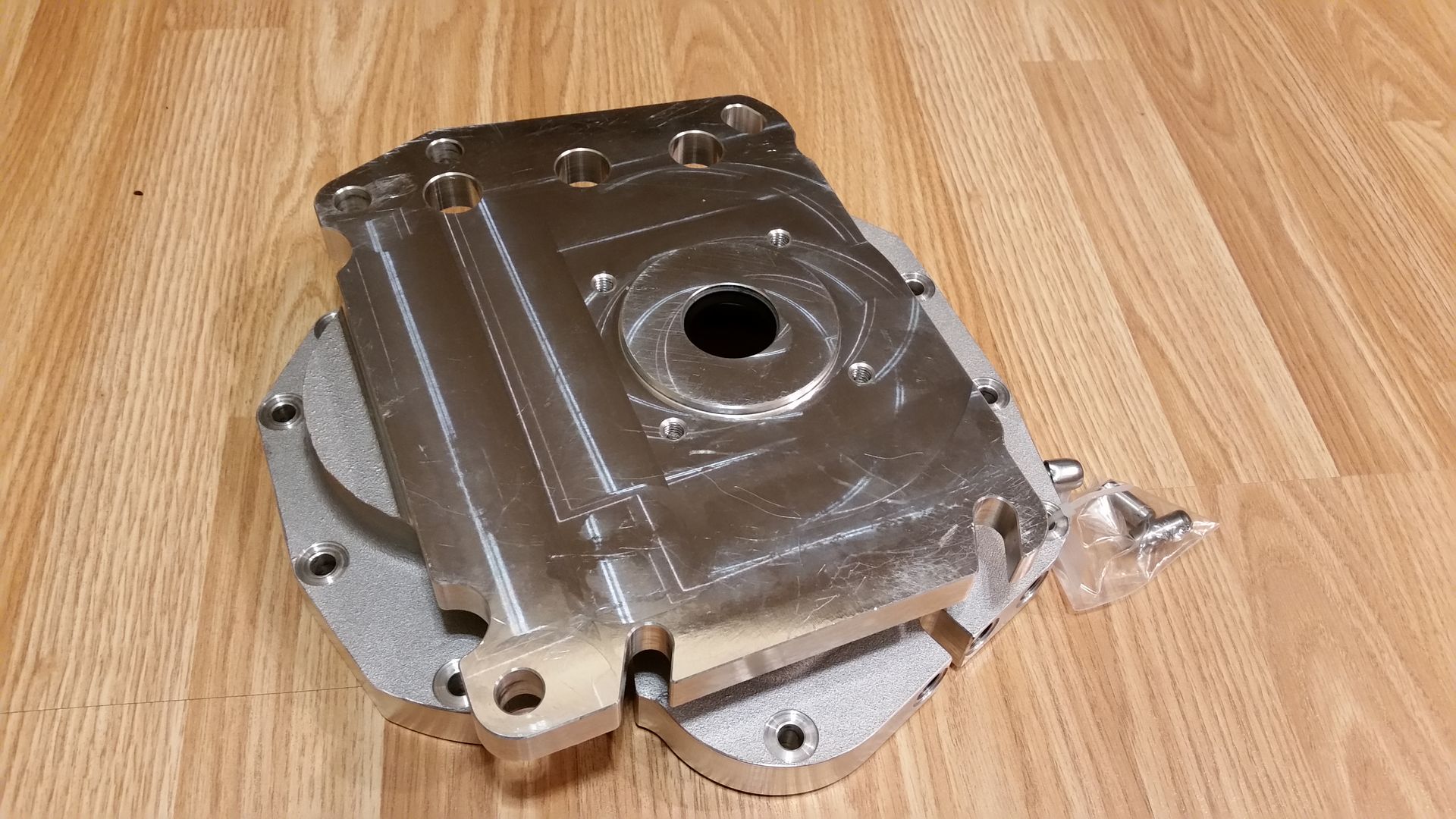

The 3650-to-TKO bellhousing plate arrived last night from Hanlon Motorsports and it's gorgeous. Still waiting on the bellhousing and input shaft. I hope to get it together later this month.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

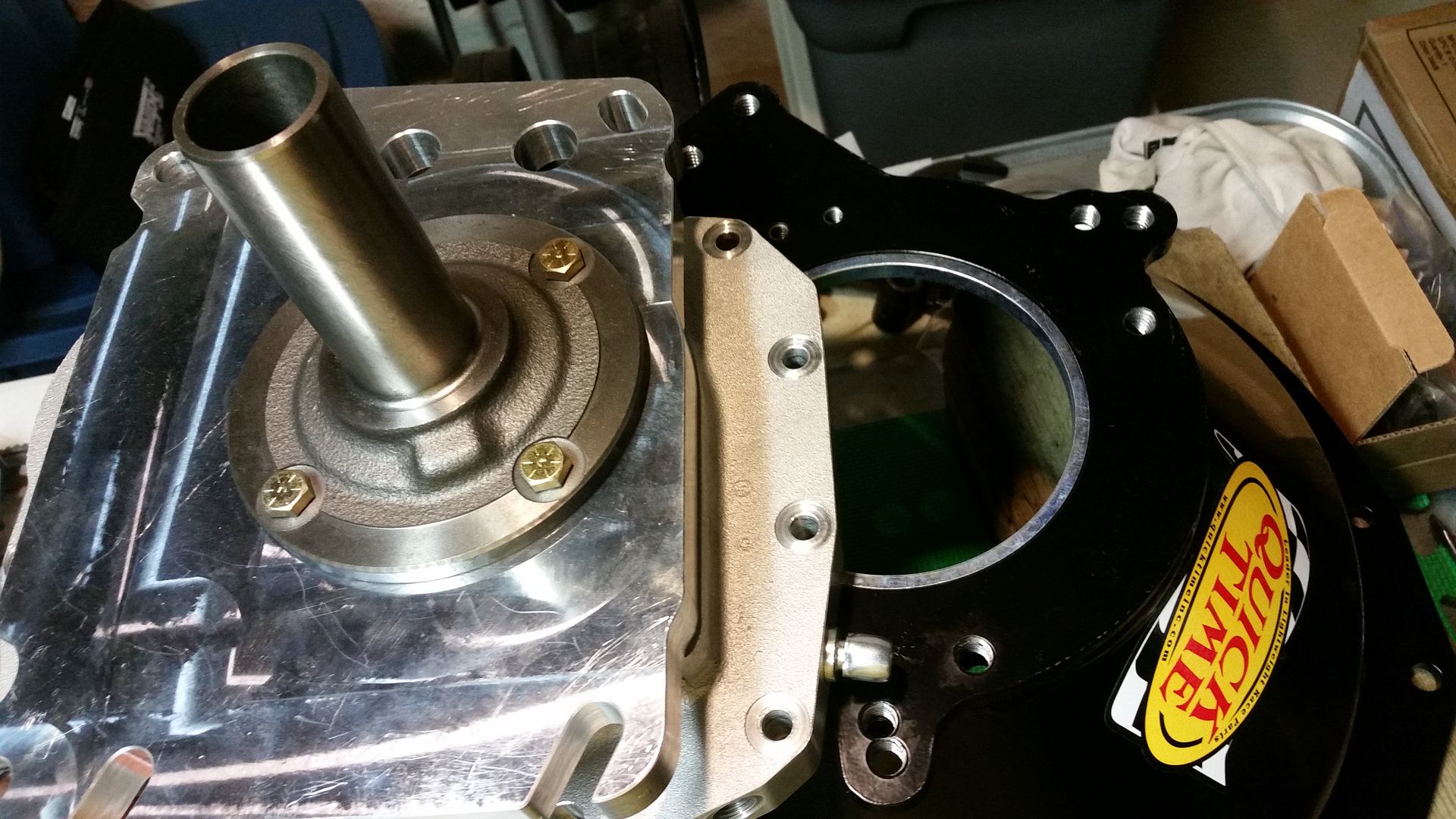

Bellhousing arrived last night!

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Drives me nuts that Quicktime drills those holes so close to eachother.

I had one for Tremec/TKO and T5 pattern (i think yours drilled the same) and I could see daylight in the thread roots of those closest two holes.

So the metal is paper thin....or less.

-JOHN

Carburetors and SAE wrenches.................

Buy Made in the USA - It Matters.

Oh that adapter plate is pretty nice.

Ed...

2012 Ram 2500 4x4, 5.7 Hemi, leveled, 35" tires

2004 Mustang GT - Comp Orange/5speed Best 1/4 11.94@113.64, 1/8 7.59@89.48, 1.57 60' - Best 60' 1.51, just a NA 2v

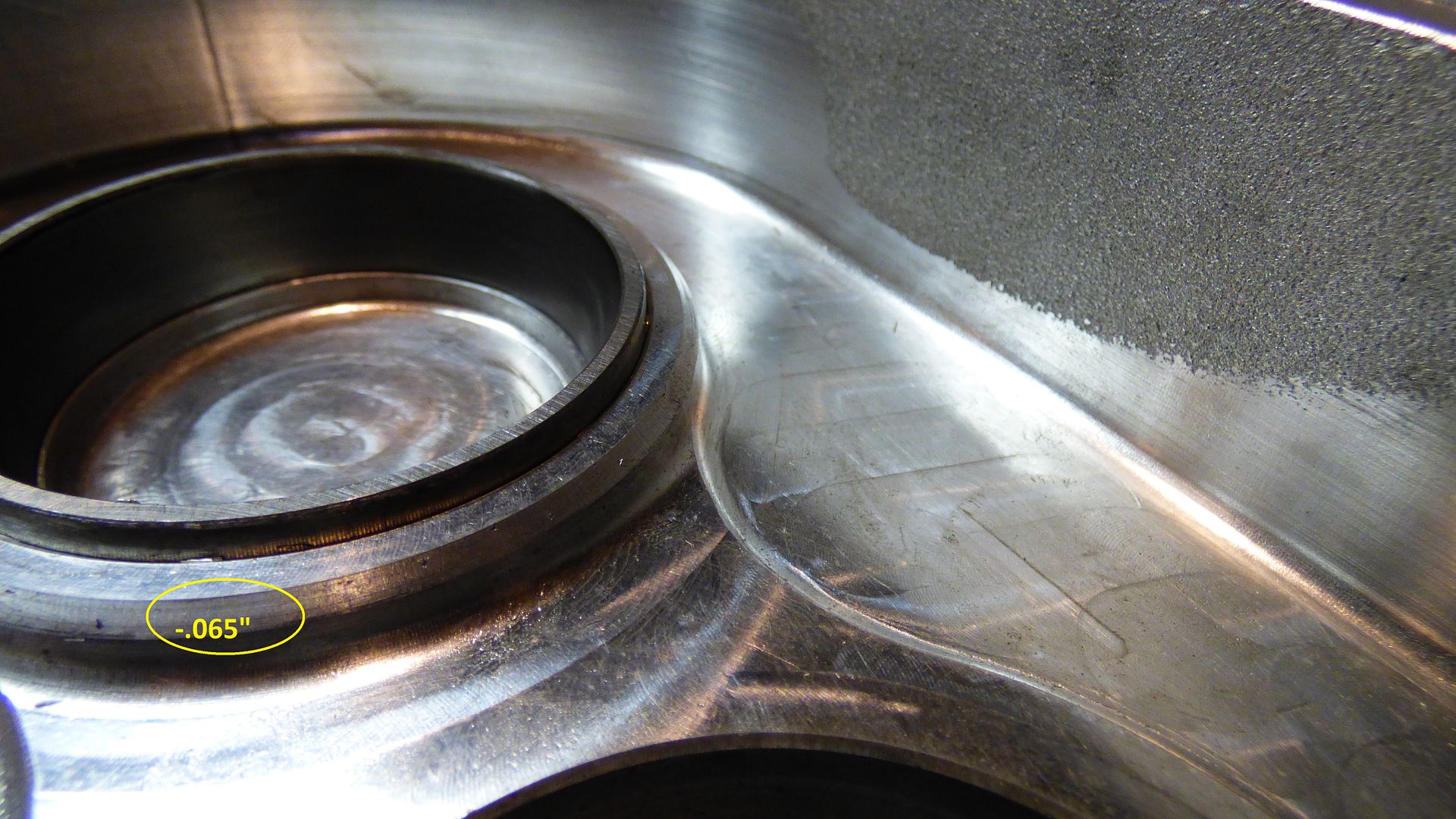

Back to it last night. I got the main shaft shimmed perfectly, but can't shim the counter shaft yet due to the bearing divot not being machined deep enough. The bottom of the bearing drags on the divot instead of the roller bearings resting on the race. It's only about .02". My buddy is a machinist so I'll take it to him soon.

This divot needs material removed from the center:

99-04 26 spline input shaft on left and 05-10 GeForce shaft on right. Right is slightly longer.

So pretty...

The T5 style bearing retainer mates into an adapter ring in the bellhousing to center it perfectly with no play.

On the T5 this retainer holds a bearing for the input shaft, but here it's simply a pass-through since the input shaft bearing rests in the adapter plate.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Make sure you indicate that bellhousing as part of your installation. Not sure what options there are for offset dowels for those deals so you might want to research that

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Hope is good, a plan is better ;) I have not messed with a QT bell that didn't need adjustment personally.

I stopped by my buddy's shop Fox's Machining and 3D Printing to pick up my modified adapter plate. Turns out it needed quite a bit more chamfer added around the cluster gear bearing hole. That is, more material removed. About .065". The GeForce cluster gear was dragging on the outer lip of the hole.

Now I can get back to shimming and then final assembly of the trans.

Once the trans is together I'll indicate (center) the LakeWood bellhousing to the motor before installing.

Last edited by sutyak; 06-01-2016 at 08:49 AM.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

I've been bouncing around a bit with the turbo Mach 1 build. Yesterday I decided it was time to get the trans together and take advantage of the AC since I'm building this in the basement of the house, rather than in the 100° garage.

Both shafts are shimmed somewhere between -.001 and 0, so a very slight preload rather than have any slop. Target is zero.

I used double-rolled pins for the shift forks rather than the stock style single layer. There are even stronger options, but I really shouldn't need them if the shifter stops are set properly. Bob Hanlon suggested an additional roll pin, drilled at an angle for added strength. Makes perfect sense to me, but I don't think I'll be abusing this car quite that much. I also don't have the machinery to confidently drill that precise of a hole without concern of damaging the fork or rod.

I'll finish up the trans soon and on to indicated the bell housing. I'm leaning towards the welded dowel approach rather than the offset dowels. Actually installing the trans will come after a few other projects with the car.

Not mounted to bell housing. Just using it as a stand.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Cool thread. Bob Hanlon seems to know his stuff. I have a 3650 built by him in my car. He was awesome to work with. Good luck with the build.

Sent from my iPhone using Tapatalk

2007 Alloy Mustang GT

1998 F150 4wd

Thanks 07Alloy.

The trans is finally together. It will still be a while before I move on to indicating the bell housing and final install.

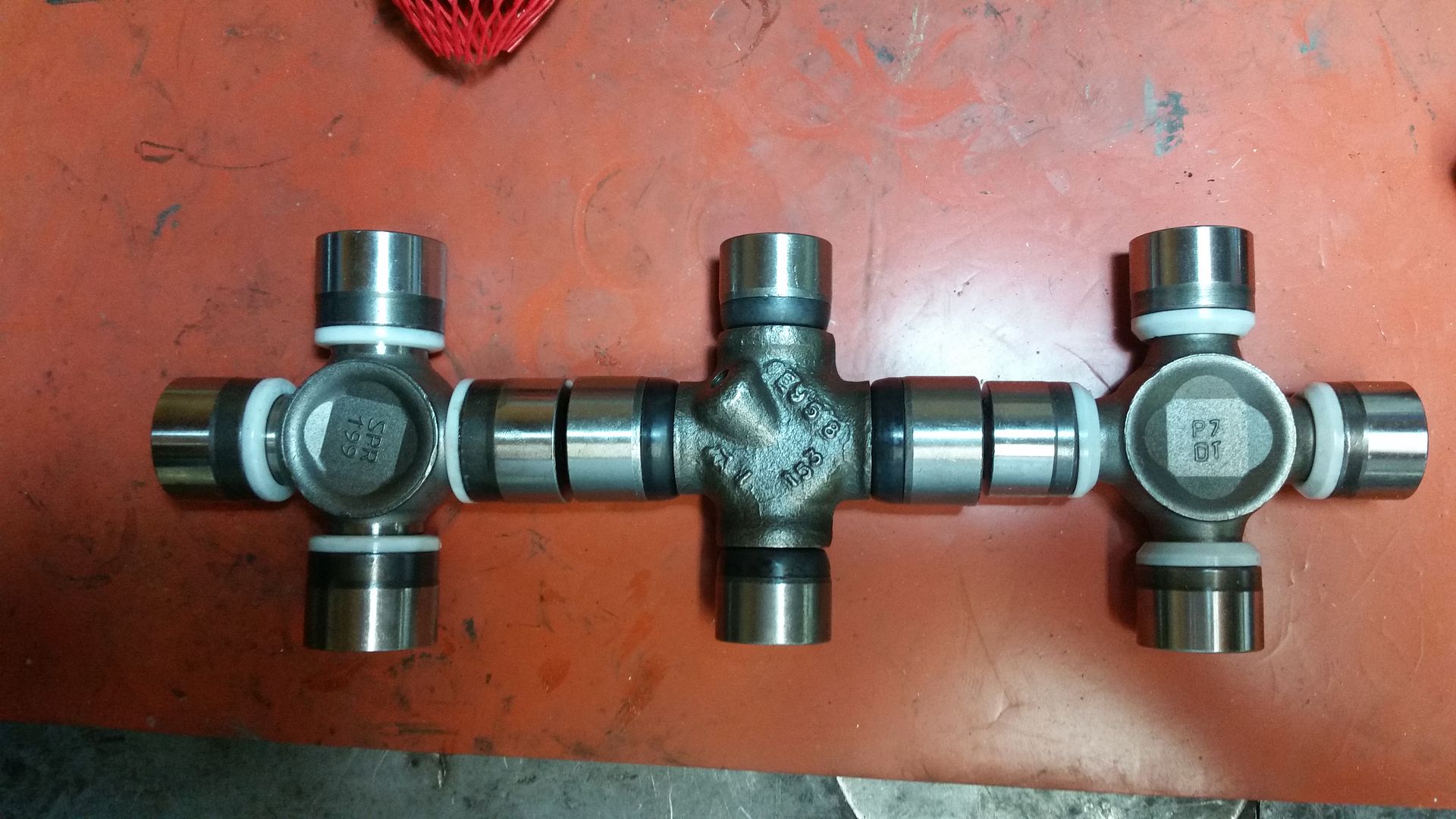

For the driveshaft I will be using a forged 1350 Mark Williams yoke with an aluminum Ford Racing shaft. The MW yoke requires a 1350/1330 combination U-joint to fit the 1330 style end of the driveshaft. It was either use the combo U-joint or go with a custom driveshaft and switch to a 1350 pinion flange.

Not very interesting just seeing a trans together. Not bolted to the bell.

MW yoke with combo U-joint. The rear flange had a lot of surface rust so I cleaned it up and painted it. Also installed a new 1330 U-joint while I was at it.

The combo U-joint is greasable, so I'll need to remember to grease it. The rear is a sealed non-greasable.

Spicer 1350, Neapco 1350/1330 combo, and Spicer 1330 U-joints.

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Something I found during assembly was a plastic bushing was previously installed in the wrong place by American Powertrain. I'd say there is a good chance this led to some stubborn shifting, as that bushing is able to slide around on the shaft. Of course there's an equal chance it didn't move much and caused no issues. Either way I installed it on the other side where it belongs.

Tough to see, but there is a shiny hard plastic ring on the upper part of the shaft. It's doing absolutely nothing installed this way. It should be on the bottom side between the shifter cup and bearing.

This is correct:

mark

'04 Mach 1. Built. Turbo. 667whp/631wtq

'06 Focus. Built. Turbo. WMI. 12.43 @ 115 (sold)

'03 Mach 1 : 12.61 @ 106.59 (sold)

he's into that, that spiritual stuff. <><

Bookmarks